COURSE OVERVIEW

PE0055 : Process Reactors: Operation, Troubleshooting, Start-Up & Shutdown

OVERVIEW

| COURSE TITLE | : | PE0055 : Process Reactors: Operation, Troubleshooting, Start-Up & Shutdown |

| COURSE DATE | : | Jun 10 - Jun 13 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Henry Beer |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 4500 |

| Request For Course Outline | ||

OTHER SCHEDULED DATES

| Date | : | Mar 03 - Mar 07 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Mar 04 - Mar 07 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Sep 02 - Sep 05 (4 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 5000 | Course Info |

| Date | : | Dec 09 - Dec 12 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

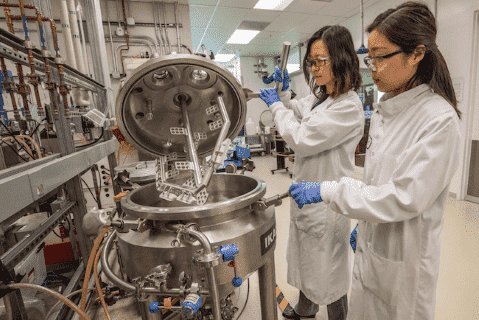

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. Process reactors are vessels designed to contain chemical reactions. The design of a process reactor deals with multiple aspects of process engineering. Process engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss or agitation. Both tank and tubular reactors can be used as continuous reactors or batch reactors, and either may accommodate one or more solids (reagents, catalyst, or inert materials), but the reagents and products are typically fluids. Most commonly, reactors are run at steady-state, but can also be operated in a transient state. When a reactor is first brought into operation (after maintenance or in operation) it would be considered to be in a transient state, where key process variables change with time.This course is designed to provide delegates with an up-to-date knowledge on the operation, troubleshooting, start-up and shutdown of process reactors. It covers the various techniques of chemical reactions; operating variables of process reactors such as pressure, temperature, hydrogen ratio, R/G ratio and LHSV; start-up guidelines and emergency shutdown procedures for process reactors; proper safety rules for reactor operation; and the reaction mechanism involved in process reactors. Participants will be able to discuss the process control and troubleshooting techniques of process reactors; employ proven start-up and shutdown procedures and have an indepth understanding of the catalyst regeneration procedure; apply feed preparation, catalyst deactivation and catalyst poisoning; and determine the different types of catalyst. link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

PE0640 : Troubleshooting Process Operations

- Date : Dec 16 -Dec 19 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register

PE0154 : Bulk Liquid Storage Management & Tanks Cleaning

- Date : Nov 10 -Nov 14 / 3 Days

- Location : Dubai, UAE

- Course Details Register

PE0114 : Process Troubleshooting and Problem Solving

- Date : Dec 08 -Dec 10 / 3 Days

- Location : Dubai, UAE

- Course Details Register

PE0010 : Oil Movement, Storage & Troubleshooting

- Date : Nov 10 -Nov 14 / 3 Days

- Location : Doha, Qatar

- Course Details Register